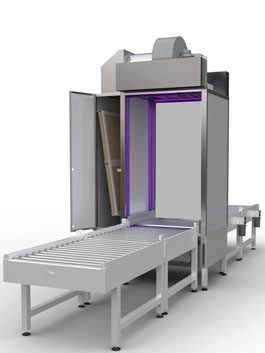

PALLETCLEANER is designed with the aim to introduce the market with a new combined technology (forced air & UVC) for cleaning and disinfection of goods loaded on pallets (glass bottles, plastic containers, cardboard, etc.) which can be included in a production cycle.

PALLETCLEANER is a perfect solution for the sectors that handles many pallets during production and for pallets containing various types of packaging packaging (such as glass bottles, plastic containers, cardboard, etc.), particularly if stored outside are subject to attack and nesting of insects, the accumulation of cobwebs, foliage and other pollutants, before entering the production cycle. Especially if used in food production processes, they must be sanitized to avoid the entry of pollutants into production environments.

FORCED AIR

CLEANING

UV-C

DISINFECTION

Safe and reliable process

The interlocked shutter closing system prevents contamination of the rooms: the doors will not be opened simultaneously and the door inside the production department is only open when the pallet is been cleaned. The technology of the treatment is safe and reliable.

OUT OF PRODUCTION AREA: Pallet waiting in the loading area

1

Fan for intake and recirculation of cleaning air

2

Box for the passage of recirculated filtered air

3

Box for roller shutter door

4

Filter compartment with stainless steel filter, removable and washable, with UV-C lamp

5

Doors to extract the dirt collection drawer for cleaning

6

Loading with independent motorization, idle / forward rollers and photocells for pallet positioning

OUT OF PRODUCTION AREA: Pallet loading in the treatment chamber

1

Single station room

2

UV emitters

3

Sensors controlling the position of the pallet

4

Loading with independent motorization, idle / forward rollers and photocells for pallet positioning

INSIDE THE PRODUCTION AREA: During treatment, both doors are closed

1

Box for roller shutter door

2

Unloading with independent motorization, idle / forward rollers and photocells for pallet positioning

INSIDE THE PRODUCTION AREA: Pallet, disinfected, ready for unloading

1

Single station room

2

UV emitters

3

Sensor controlling the position of the pallet

4

Unloading with independent motorization, idle / forward rollers and photocells for pallet positioning

| Pallet Dimensions | 1200 mm x 1000 mm Max height 2100 mm |

||

| Capacity | 50 L | ||

| Maximum mass | 1000 kg for each module | ||

| Temperature | Based on environmental temperature 0-40°C | ||

| Forced Air | 5.6 kW Centrifugal Fan and adjustable flow rate up to 7200 m3/h | ||

| UV | 1.1Kw UV-C | ||

| Voltage | 400V (3F + N + PE) | ||

| Frequency | 50 Hz | ||

| Installed power | 14 kW | ||

| Treatment room | L.180 x P. 150 x H.255 cm, attrezzato con:

|

||

| Loading conveyor | L. 150 x P. 140 cm

|

||

| Unloading conveyor | L. 150 x P. 140 cm

|

||

| Productivity | 12 pallet/hour (minimum treatment 1 pallet every 5 minutes) | ||

| Industry 4.0 | Certificabile | ||

| Mark | CE | ||

| Language of Panel and Manual | English | ||

WHY CHOOSE PALLETCLEANER

2 IN 1 – PALLETCLEANER is a combinable technology oven which has been designed for industrial use especially for all the treatments in the entrance of the material in the productive areas. It has 2 main functions: cleaning and disinfection.

CONSUMPTION – Respecting the GO GREEN concept, you can save up energy. The combination of the heating technology permits high energy efficiency and reduce process time and consumption.

MANAGEMENT AND CONNECTIVITY – The oven is programmable from the operator panel, easy to operate touch screen, can store maximum number of recipes. The front panel is designed with a visual signaling system that indicates the indications the progress or the status of the oven.

MAINTENANCE – PALLETCLEANER is simple and easy to maintain; ordinary cleaning can be carried out safely by a single operator. The cabin can be easily cleaned at every corner, the technical cabinet is accessible by opening the sheet plated on the front, the filter can be removed separately and washed, the electric board is remoted in the productive area, all the command are remoted in an unique command center.